Four-Wheel Steer Loader AL735

Four-Wheel Steerable Loader

Steering 4WS (four-wheel steering):

- Steerable front and rear wheels.

- Hydraulic/electronic angle coordination.

Advantages

- Flexibility: Ideal for confined areas (urban construction, small mines).

- Precision: Precise control for pipeline, trenching, and interior demolition work.

Four-Wheel Steer Excavator: Advantages and Features

The four-wheel steer excavator is a piece of mechanical engineering equipment with a special steering function, offering multiple advantages over traditional excavators:

Steering Mode and Operating Principle

It incorporates a 4WS (Four-Wheel Steering) system, which allows steerability not only for the front wheels but also for the rear wheels. Through hydraulic or electronic control, the steering angles of the front and rear wheels are coordinated, achieving (flexible) steering patterns, such as:

Steering (Co-steering): The front and rear wheels turn in the same direction, increasing the turning radius and improving stability at high speeds.

Steering (Counter-steering): The front and rear wheels turn in opposite directions, significantly reducing the turning radius and improving maneuverability in tight spaces.

Performance Advantages

Maneuverability (Maneuvering Flexibility): In areas with limited space, such as narrow construction sites, urban streets, or underground projects (such as underground network installation or internal scrapyards), it can easily rotate, turn around, and move, improving work efficiency.

Operational Accuracy: During tasks requiring high positioning accuracy, such as pipe laying or trenching, it allows for more precise control of the machine body's position and angle, improving construction quality and accuracy.

Movement Stability: At high speeds or on uneven terrain, the four-wheel steering system adjusts the angle of the rear wheels to maintain machine body balance, reducing the risk of rollover.

Application Areas, Widely used in:

Urban Construction: Road repairs, scrapping, and refurbishment of buildings, etc.

Small-Scale Mining: Working in narrow mine tunnels.

Agricultural hydraulic construction: Projects in narrow fields, such as the excavation of canals or the installation of irrigation systems.

| Modelo | AL735 |

|---|---|

| Fabricante | SAFORD - China |

| Motor | |

| Modelo | yunnei4102 |

| Potencia nominal | 76,7kw |

| Tipo | Motor diesel de cuatro tiempos |

| Desplazamiento | 3760cc |

| Rendimiento | |

| Capacidad máxima de elevación | 3500kg |

| Capacidad máxima de elevación a la distancia máxima de extensión | 2800kg |

| Capacidad a la máxima extensión del brazo | 1100kg |

| Altura máxima de elevación | 7000mm |

| Distancia máxima horizontal de extensión del brazo | 3300mm |

| Gradiente | 30% |

| Peso de la máquina | 8500kg |

| Velocidad máxima | 40km/h |

| Ejes diferenciales | |

| Modelo de conducción | 4WS (dirección de cuatro ruedas), dirección cangrejo, 2WS (dirección de dos ruedas) |

| Eje delantero | Rígido |

| Eje trasero | Oscilante |

| Freno de movimiento | Freno de servicio de disco en las 4 ruedas con sistema hidráulico de doble circuito de aire comprimido |

| Freno de estacionamiento | Freno de estacionamiento negativo |

| Neumáticos | 405/70 - 20 |

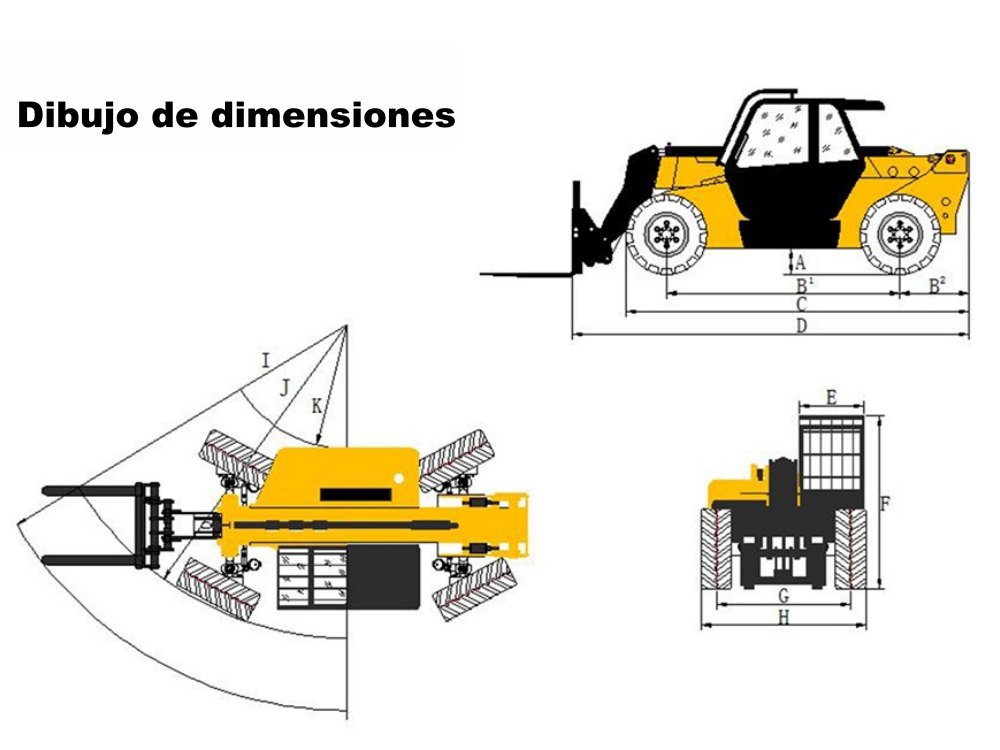

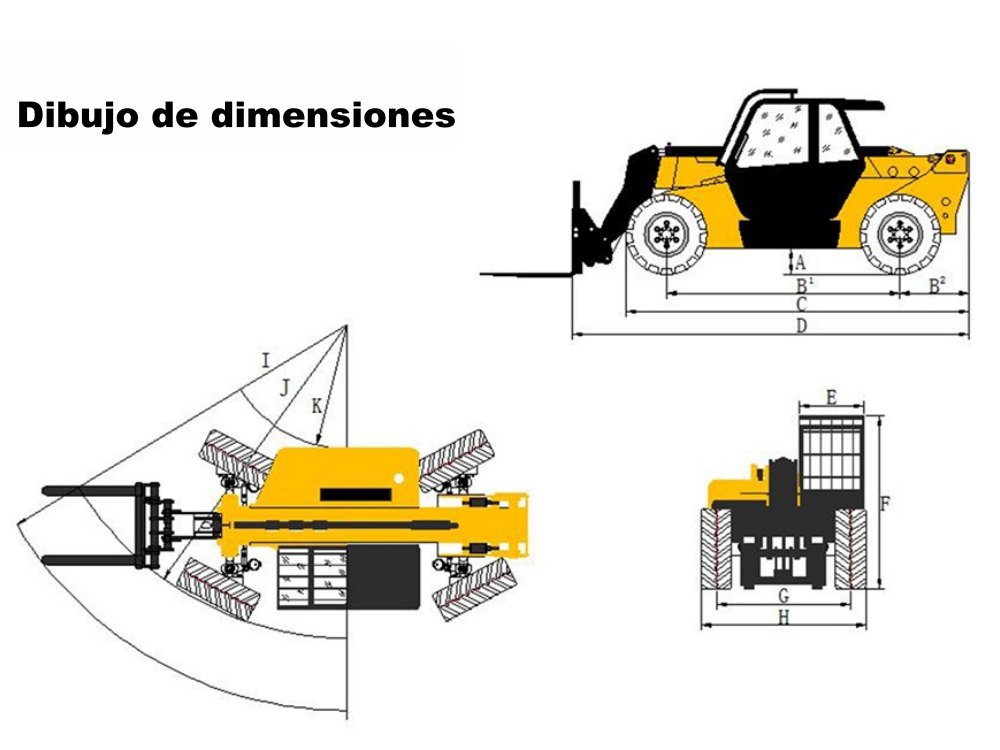

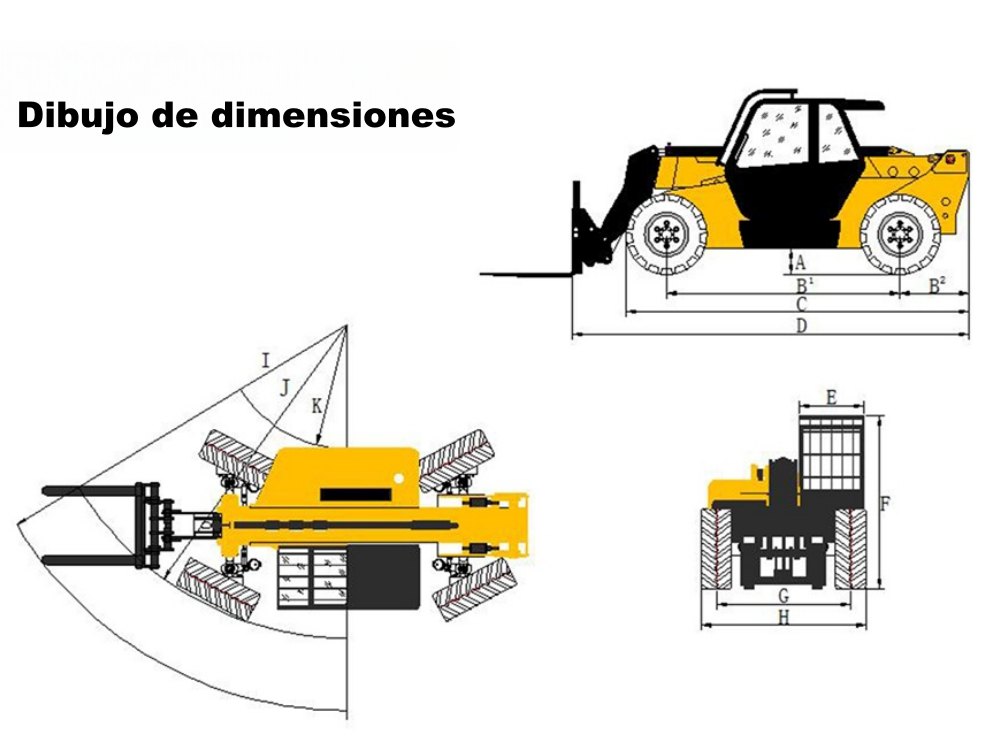

| Dimensiones | |

| Longitud (sin dientes de agarre) D | 5300mm |

| Altura F | 2300mm |

| Ancho H | 2150mm |

| Distancia del eje B1 | 2950mm |

| Distancia entre neumáticos G | 1760mm |

| Ancho de la cabina E | 910mm |

| Altura de paso A | 370mm |

| Distancia entre los neumáticos delanteros al chasis trasero C | 4050mm |

| Longitud estándar de los dientes de agarre | |

| Opciones | |

| Advertencia y limitación de sobrecarga | |

| Chasis giratorio(+ - 6) | |

| Laterales | |

| Posicionador de dientes de agarre | |

| Cabina elevable | |

| Gran cubeta para carga en volumen | |

| Cubeta normal para construcción | |

| Plataforma de trabajo (giratoria, plataforma de trabajo giratoria, etc.) | |

| Aditamentos (gancho, grapadora, taladro auger, cubeta mixta, taladro fijo, 4 en 1, cubeta de arrastre, baler, manipulador) |